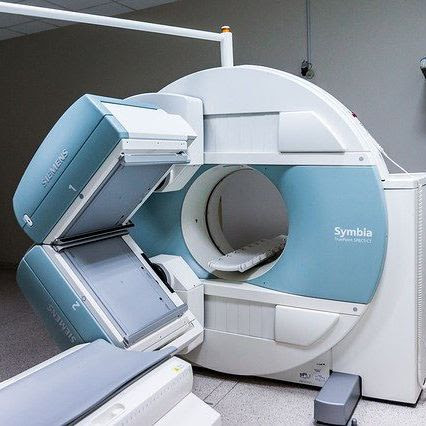

Non-magnetic fasteners play a crucial role in various applications where avoiding magnetic interference is essential. Common examples include cryogenic environments and medical fields like MRI machines. This newsletter delves into some specialty metal fasteners designed specifically for non-magnetic requirements.

Non-magnetic fasteners play a crucial role in various applications where avoiding magnetic interference is essential. Common examples include cryogenic environments and medical fields like MRI machines. This newsletter delves into some specialty metal fasteners designed specifically for non-magnetic requirements.

Inconel Bolts

Inconel Bolts

Non-magnetic fasteners offering corrosion resistance, high strength, and high-temperature performance

Inconel 625 and 718 bolts each possess unique attributes tailored for non-magnetic applications. Inconel 625 screws exhibit exceptional corrosion resistance—almost on par with Hastelloy—and boast impressive strength, with a tensile strength of 144 ksi and a maximum operating temperature of 1800°F. Meanwhile, Inconel 718 bolts are celebrated for their extraordinary high strength—about twice as strong as Inconel 625—and outstanding creep-rupture strength up to 1300°F, with an operational limit of 1800°F.

Titanium Bolts

Titanium Bolts

Non-magnetic fasteners providing lightweight strength and chloride/saltwater resistance

A Grade 2 titanium screw excels in resisting chlorides and saltwater, making it suitable for both dynamic and static seawater environments, even surviving in ocean depths exceeding a mile for decades. Additionally, Grade 5 titanium bolts are renowned for their excellent strength-to-weight ratio—four times stronger than 316 stainless steel while being nearly half the weight. Their versatility extends beyond marine applications to medical and military uses.

Aluminum 7075

Aluminum 7075

An economical option for a strong, lightweight non-magnetic fastener

Widely utilized in aerospace applications, Aluminum 7075 bolts are favored for their high strength-to-weight ratio. These bolts provide strength comparable to many steel grades but weigh significantly less. Furthermore, Aluminum 7075 bolts can be heat-treated to meet diverse strength specifications.

Common Non-Magnetic Applications

- Aircraft Maintenance & Overhaul

- Aluminum & Other Metal Smelting

- Applications Requiring Cryogenic Temperatures

- Electronics Manufacturers (Clean Room Maintenance)

- Hospitals & Clinics Magnetic Resonance Imaging (MRI - Maintenance on or near)

- Mine Sweepers

- Nuclear Products & Testing Machines

- Precision Magnetic Equipment (Compasses & Electronics - Maintenance on or near)

- Public Utilities: Gas, Electric & Telecommunication

- Radar Transmission Centers

As industries continue to advance, the demand for specialized non-magnetic fasteners grows. Whether it's ensuring the integrity of medical imaging equipment or supporting aerospace innovations, these fasteners are indispensable. Understanding the unique properties of materials like Inconel, titanium, and aluminum ensures engineers can select the optimal solutions for their projects. The versatility of these fasteners opens doors to new possibilities across multiple sectors, reinforcing their importance in modern technology.

Special Shape Fabric Air Duct,Ventilation Duct Machine,Fiberglass Air Duct Fabric,Insulated Fabric Duct

Jiangsu Buna Technology Development Co. , Ltd. , https://www.bunaduct.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)