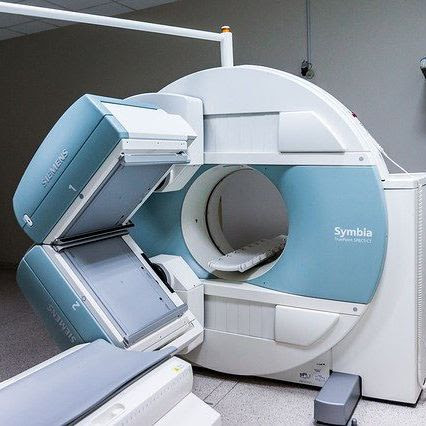

Fasteners that don't attract magnets play a crucial role in various industries where magnetic interference could cause issues. From cryogenics to medical equipment like MRI machines, non-magnetic fasteners ensure smooth operations without compromising safety or performance. This edition of our newsletter focuses on some specialized metallic fasteners designed specifically for non-magnetic applications.

Fasteners that don't attract magnets play a crucial role in various industries where magnetic interference could cause issues. From cryogenics to medical equipment like MRI machines, non-magnetic fasteners ensure smooth operations without compromising safety or performance. This edition of our newsletter focuses on some specialized metallic fasteners designed specifically for non-magnetic applications.

Inconel Bolts

Inconel BoltsCorrosion-resistant, high-strength fasteners capable of withstanding extreme temperatures

Inconel 625 and 718 bolts stand out due to their unique properties. The Inconel 625 bolts offer superior corrosion resistance, comparable to Hastelloy, along with impressive tensile strength of 144 ksi and the ability to function effectively up to 1800°F. Meanwhile, Inconel 718 bolts are celebrated for their exceptional high strength—approximately twice that of Inconel 625—and remarkable creep-rupture strength, making them ideal for environments reaching temperatures as high as 1300°F and usable up to 1800°F.

Titanium Bolts

Titanium BoltsLightweight yet robust fasteners resistant to chlorides and saltwater

Aluminum 7075

Aluminum 7075A cost-effective option offering strength and lightweight characteristics

Common Non-Magnetic Applications

- Aircraft Maintenance & Overhaul

- Aluminum and Other Metal Smelting

- Applications Requiring Cryogenic Temperatures

- Electronics Manufacturers (Clean Room Maintenance)

- Hospitals & Clinics: Magnetic Resonance Imaging (MRI - Maintenance on or near)

- Mine Sweepers

- Nuclear Products & Testing Machines

- Precision Magnetic Equipment (Compasses & Electronics - Maintenance on or near)

- Public Utilities: Gas, Electric & Telecommunication

- Radar Transmission Centers

Non-magnetic fasteners are indispensable in fields where magnetic interference poses risks. Whether it's maintaining sensitive medical equipment or ensuring safety in extreme environments, these specialized fasteners play a vital role. From the durability of Inconel bolts to the versatility of titanium and aluminum options, each material brings unique advantages tailored to specific needs. As industries continue to push boundaries, understanding the right fastener for the job becomes increasingly important. Stay ahead by exploring how these materials can enhance your projects and operations!

Insulated Composite Insulation Air Duct

Insulated Composite Insulation Air Duct,Fabric Air Duct Colling Systems,Fabric Duct,Fabric Ductwork

Jiangsu Buna Technology Development Co. , Ltd. , https://www.bunaduct.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)