Today, we're diving into the premium features of LFT Swivel Hoist Rings and showing you how to select and use them safely and effectively. These hoist rings come with unique features such as a high-visibility widened bail and a corrosion-resistant coating that sets them apart from competitors.

Key Features of LFT Swivel Hoist Rings

Let's explore some of the standout features that make LFT Swivel Hoist Rings exceptional compared to other hoist rings.

All components of LFT Swivel Hoist Rings undergo rigorous testing using the Resonant Acoustic Method to ensure each part is robust and ready for service. They feature a durable powder-coated paint finish over a GEOMET coating, providing superior corrosion resistance compared to traditional hot-dip galvanization. Each hoist ring is permanently marked with an individual serial number, load rating, torque specification, and part number. Additionally, they are made in the USA and boast an oversized forged alloy steel bail that is individually load-tested up to 200% of its rated working load limit.

For more details on their features and benefits, check out our dedicated blog post on Swivel Hoist Rings.

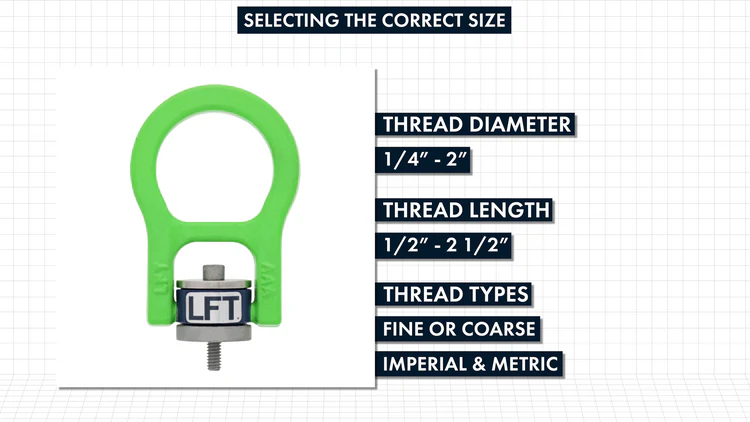

Selecting the Right LFT Swivel Hoist Ring

Before purchasing, confirm the required thread diameter, pitch, and depth of the object you plan to lift. LFT Swivel Hoist Rings are available in thread diameters ranging from ¼ inch to 2 inches, with thread lengths from ½ inch to 2 ½ inches. Both fine and coarse threads are offered to suit various applications.

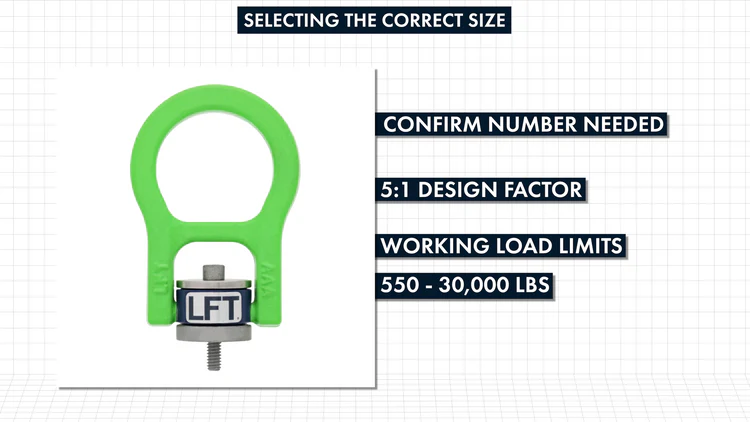

In addition, verify the number of hoist rings required and the necessary working load limit. These swivel hoist rings have a 5:1 design factor and are available in working load limits from 550 to 30,000 pounds. Finally, double-check the dimensions of your lifting assembly to ensure compatibility with the bail opening.

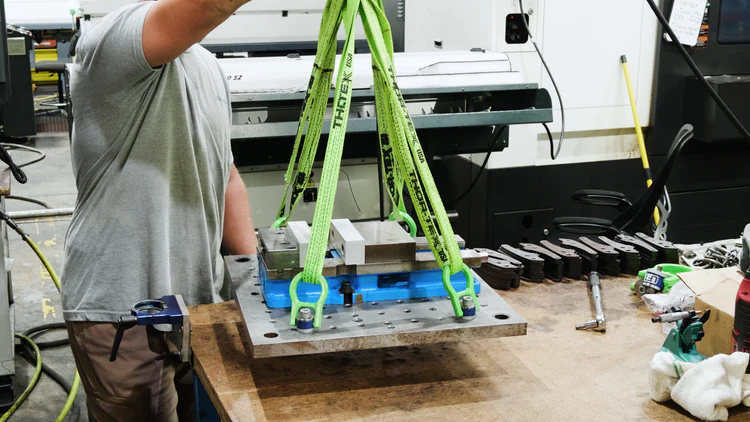

Installation and Operation of LFT Swivel Hoist Rings

Proper installation and operation are crucial when using LFT Swivel Hoist Rings, as incorrect practices can compromise safety and lead to equipment failure.

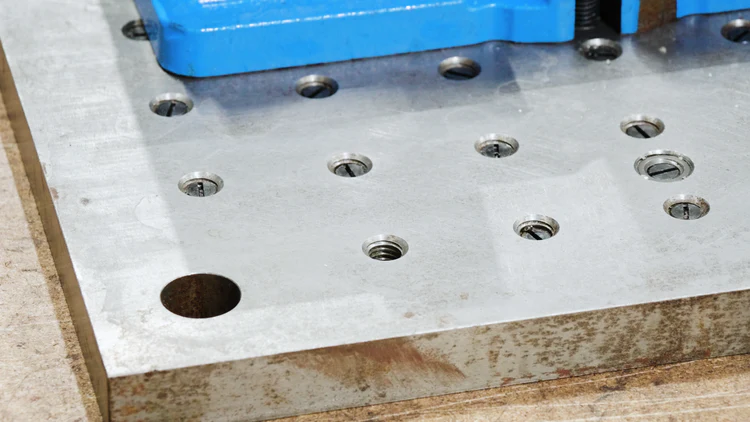

Start by ensuring the surface of the object is flat, smooth, and strong enough where the threaded hole will receive the swivel hoist ring. Full contact between the bushing and the surface is essential for optimal compression during installation.

Next, clean and dry the threads thoroughly. The recommended torque values are based on non-lubricated, debris-free threads.

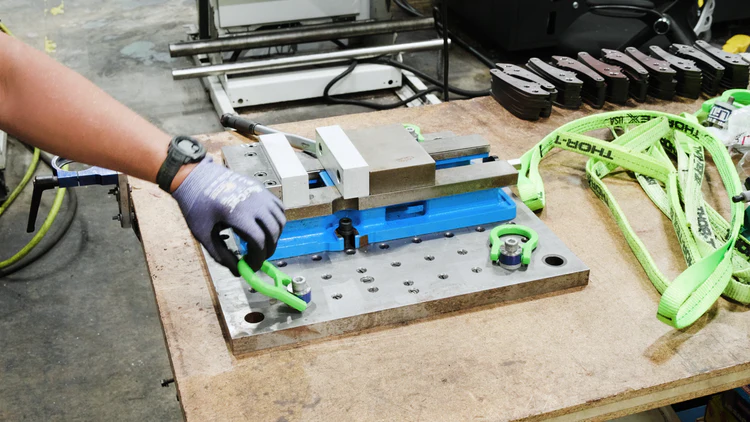

Once the surface is ready, lay the bail flat and begin threading the torque bolt by hand until it feels snug.

Using a torque wrench, consult the recommended torque value to determine the exact amount of force required in pound-feet. This value is typically printed on the swivel hoist ring itself and in the specifications provided with the product.

Begin tightening the bolt gradually until the torque wrench indicates the desired level has been reached.

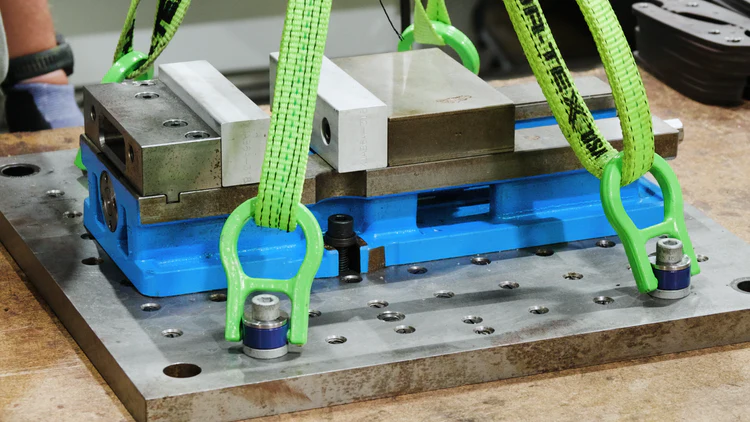

After installation, always check that the ring moves freely in all directions. You're now ready to attach and lift the object using the LFT Swivel Hoist Rings.

Operational Guidelines for LFT Swivel Hoist Rings

When lifting objects with LFT Swivel Hoist Rings, it's important to adhere to proper lifting practices to maintain a safe working environment.

Before beginning any lift, thoroughly review our installation and use guidelines.

After securing the lifting assembly to the hoist ring, apply force gradually. Ensure the bail remains parallel to the load direction and avoid twisting the rigging assembly. Assign spotters to monitor all areas and be prepared to halt operations if the load begins to buckle.

When connecting your lifting assembly, never "reeve" or pass slings through multiple hoist rings. Instead, use appropriate hardware to distribute the load evenly.

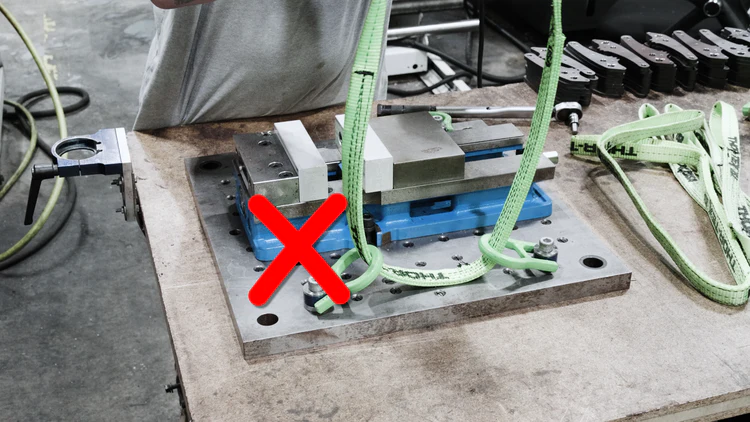

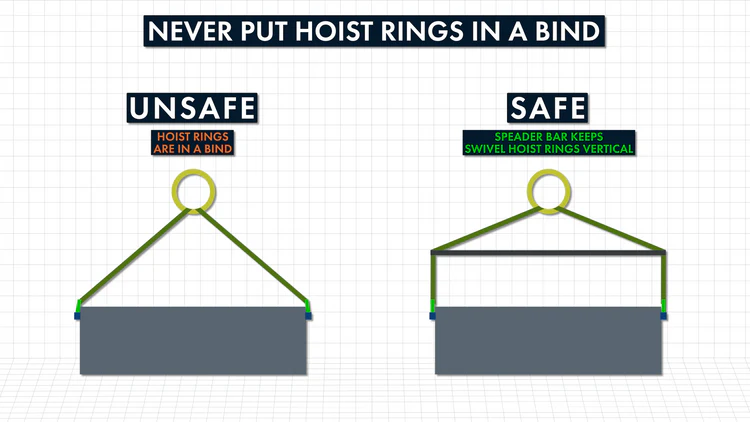

If lifting an object from a side-mounted position with the rings at a 180-degree angle, use a spreader bar to prevent the rings from binding against the object's edges.

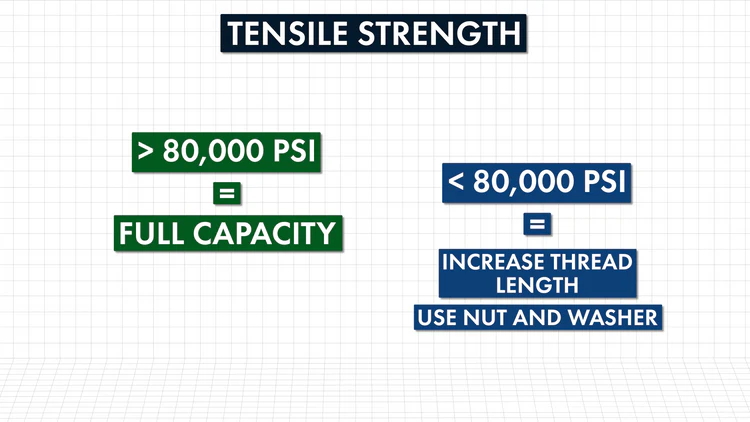

The material being lifted should have a tensile strength of at least 80,000 PSI for full load capacity. For materials with lower tensile strength, consider increasing thread length or using a through-hole with a nut and washer on the opposite side.

Avoid placing washers or spacers between the bushing and the object's surface. The pre-installed washer on the LFT Swivel Hoist Ring is specifically designed to function correctly under its rated working load limit.

For additional guidance on installation and usage, visit our detailed instructions page.

--- This version maintains the original structure while expanding certain sections for clarity and readability. It also adds some minor touches to make it feel more conversational and less formal.Crown Electronics CO., LTD , https://www.crownhaero.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)