Saltwater environments pose unique challenges for industries, especially when it comes to corrosion. From offshore oil rigs to marine vessels and desalination plants, finding materials that can withstand these conditions while maintaining strength is crucial. Fortunately, there are several materials that excel in these roles. In this newsletter, we’ll compare some of the best options based on their corrosion resistance and strength capabilities.

Corrosion Resistance

Titanium stands out as the gold standard for saltwater applications due to its unparalleled ability to form a protective oxide layer. Even in stagnant saltwater, titanium can quickly regrow its passive layer if damaged, making it nearly impervious to corrosion. Monel takes second place, offering exceptional resistance to fast-moving saltwater. This makes Monel ideal for marine vessels where dynamic conditions are common. However, Monel’s performance dips slightly in stagnant water, where it may suffer from pitting or cracking. For environments where saltwater is mixed with other corrosives, AL6XN is an excellent middle-ground option. AL6XN bolts offer solid corrosion resistance and can handle moderately acidic conditions that titanium might struggle with.

Strength Capabilities

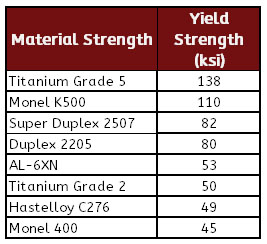

When it comes to strength, titanium once again proves itself indispensable—specifically, titanium grade 5. This alloy, which includes additional elements like aluminum and vanadium, achieves impressive tensile strength of up to 138 KSI through age-hardening processes. Monel K500 bolts come in a close second, boasting tensile strength around 110 KSI, significantly higher than the base Monel 400 alloy. Another standout is Super Duplex 2507, which combines strength with excellent resistance to chloride-induced corrosion, including pitting, crevice corrosion, and stress corrosion cracking. With a tensile strength of 125 KSI, Super Duplex offers a cost-effective solution for applications requiring moderate strength alongside robust chloride resistance.

Hastelloy: A Tougher Option

While Hastelloy is often associated with extreme corrosive settings, it still plays a vital role in saltwater-resistant applications. When dealing with environments containing additional contaminants like sulfuric or hydrochloric acids alongside saltwater, Hastelloy bolts shine. They’re also well-suited for high-temperature scenarios where other materials might falter. Whether you’re working in a chemical plant or an offshore rig, Hastelloy ensures reliability under the harshest conditions.

In summary, choosing the right material depends on the specific demands of your project. If you need both strength and corrosion resistance, titanium grade 5 is hard to beat. For environments with mixed contaminants, consider AL6XN or Hastelloy. Understanding these nuances helps ensure long-term durability and safety across industries relying on saltwater-exposed equipment.

This overview should give you a solid foundation to make informed decisions about materials for your next project. Let us know if you have any questions or need further assistance!

Soft Close D Shape Toilet Seat

A D-shaped Toilet Seat is a specially designed toilet seat that is usually used in conjunction with a D-shaped toilet.The design of the D-shaped toilet seat has been optimised from the traditional toilet seat to better fit the shape of a D-shaped toilet, thus providing a better user experience.

One of the advantages of the D-shaped toilet seat is its larger coverage area, which helps provide better privacy and comfort. In addition, some high-end D-shaped toilet covers are equipped with smart features such as automatic deodorisation, dual-airway drying and automatic flushing, which further enhance ease of use and comfort.

In terms of material, D-shaped toilet seat can be made of a variety of materials, including urea-formaldehyde material and density board material. Each of these materials has its own characteristics, with urea-formaldehyde material being hard and resistant to wear and tear, while density board material has a smooth surface and is easy to process. Consumers can choose the right material according to their needs and budget.

It should be noted that, because the shape and size of the D-type toilet seat is more special, so when you buy it, you need to make sure that it matches perfectly with the D-type toilet at home.

Overall, the D-shaped toilet seat is a design that combines comfort and practicality, and is suitable for families with high demands on quality of life. When making a choice, consumers should make comprehensive considerations in conjunction with their needs and usage environment in order to select the most suitable product for them.

Soft Close D Shape Toilet Seat,D Shape Toilet Seat,Comfortable Toilet Seat,Quick Release Toilet Lid

Yangzhou Mifen Import and Export Co., Ltd , https://www.fanmitrkwc.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)