The Heat-Affected Zone (HAZ) is one of the most critical aspects of welding metallurgy. It's the area of base metal that is not melted but has undergone significant changes in its microstructure due to exposure to high temperatures during welding. The HAZ can affect the mechanical properties of the metal, such as its hardness, toughness, and susceptibility to cracking. Controlling the HAZ is crucial in maintaining the integrity of the weld joint and the overall structure.

1. What is the Heat-Affected Zone (HAZ)?

The HAZ refers to the portion of the base material adjacent to the weld that has experienced thermal cycles (heating and cooling) intense enough to alter its microstructure, but not enough to melt it. While the weld pool itself forms the fusion zone (FZ), the HAZ surrounds this area and is divided into various temperature gradients, each affecting the material differently.

In many materials, especially carbon steels, stainless steels, and alloy steels, the HAZ is a critical factor in weld performance. The thermal history that the HAZ experiences during welding can induce hardness, brittleness, grain growth, and potential cracking if not carefully managed.

2. Metallurgical Changes in the HAZ

The changes that occur in the HAZ depend on several factors, including the material composition, the welding process, and the cooling rate. The HAZ can be broken down into three key subzones:

-

Coarse Grain Heat-Affected Zone (CGHAZ): Closest to the fusion zone, the CGHAZ experiences the highest temperatures just below the melting point of the base material. In steel, this causes grain growth and significant microstructural changes. Coarser grains result in reduced toughness, making the material more susceptible to cracking.

-

Fine Grain Heat-Affected Zone (FGHAZ): As you move away from the fusion zone, the metal experiences lower temperatures, leading to finer grain structures. Finer grains improve toughness and ductility compared to the coarse-grain zone.

-

Intercritical and Subcritical HAZ: These regions are farthest from the fusion zone and experience temperatures below the transformation point. The subcritical HAZ undergoes tempering, while the intercritical zone sees partial phase transformations. In steels, this area might include a mix of ferrite and pearlite or other phases, depending on the material.

In materials like aluminum alloys, the HAZ can cause precipitate dissolution and over-aging, reducing the material’s strength, which can be problematic in aerospace applications.

3. Effect of Welding Parameters on the HAZ

The extent and properties of the HAZ are highly dependent on the welding process parameters:

-

Heat Input: This is a critical factor influencing the size and properties of the HAZ. Heat input is determined by the welding process, current, voltage, and travel speed. A high heat input increases the size of the HAZ and can lead to grain coarsening and softening of the base metal in steels, increasing the risk of cracking.

Formula: Heat Input (kJ/mm) = (Voltage * Current * 60) / (1000 * Travel Speed)

-

Cooling Rate: The cooling rate after welding has a significant impact on the microstructural evolution of the HAZ. Rapid cooling in steels can lead to the formation of martensite, a hard but brittle phase, making the weld joint more prone to cracking. Controlled cooling, such as post-weld heat treatment (PWHT), can relieve residual stresses and temper martensitic structures, enhancing toughness.

-

Welding Technique: The use of multi-pass welding (especially in thicker materials) can alter the thermal cycles experienced by the HAZ, with subsequent passes reheating and tempering previously welded areas. This can improve the toughness of the HAZ.

4. Common Problems Associated with the HAZ

-

HAZ Cracking: Cracking in the HAZ is a common issue, especially in high-strength steels or thick sections. Hydrogen-induced cracking (HIC) or cold cracking often occurs due to the combination of a high hardness HAZ, residual stresses, and hydrogen absorption during welding.

-

Brittleness and Hardness: If the HAZ experiences too much grain coarsening or forms martensitic structures in steels, it can become excessively hard and brittle, increasing the risk of brittle fracture under stress.

-

Softening in Aluminum: In heat-treated aluminum alloys, such as 6061, the HAZ can experience precipitate dissolution, leading to softening. The strength of the aluminum alloy is significantly reduced in the HAZ compared to the parent material.

5. Controlling the HAZ

To ensure optimal weld performance and minimize problems in the HAZ, several control methods are used:

-

Preheating: Preheating the base material before welding helps reduce the cooling rate, minimizing the risk of HAZ hardening and cracking, especially in carbon steels. Preheating temperatures depend on the material but can range from 150°C to 300°C.

-

Post-Weld Heat Treatment (PWHT): PWHT is a thermal process applied after welding to relieve residual stresses and improve toughness in the HAZ. In steels, PWHT reduces the hardness of martensite and improves ductility. The process typically involves heating the welded assembly to a temperature just below the transformation range and holding it for a specified time.

-

Low-Hydrogen Electrodes: Using low-hydrogen electrodes (such as E7018 for stick welding) or properly controlled shielding gases reduces hydrogen content in the weld, minimizing the risk of hydrogen-induced cracking in the HAZ.

-

Optimizing Heat Input: By using controlled heat input processes, such as pulsed MIG or TIG welding, welders can reduce the size of the HAZ and minimize grain growth. Pulsed techniques deliver high energy only during certain parts of the welding cycle, which controls the amount of heat absorbed by the base material.

6. Modern Techniques to Minimize HAZ Damage

Recent advancements in welding technology offer new ways to reduce the impact of the HAZ:

-

Laser Welding: Laser welding provides a highly focused heat source, minimizing heat input and significantly reducing the size of the HAZ. This technique is ideal for materials like stainless steel and titanium.

-

Electron Beam Welding: Like laser welding, electron beam welding delivers high energy density, reducing the HAZ and associated metallurgical changes.

Conclusion

The Heat-Affected Zone is a complex but critical aspect of welding that can significantly impact the performance of welded joints. Understanding how metallurgical changes in the HAZ occur and how to control them through process parameters, preheating, and post-weld treatments is essential for achieving strong, reliable welds. Proper control of the HAZ ensures longevity, reduces cracking risks, and optimizes the mechanical properties of the welded joint.

For more insights on welding techniques and advanced equipment, contact Quantum Machinery Group at Sales@WeldingTablesAndFixtures.com or call (704) 703-9400.

Overview

The 4-20mA PH Sensor is a high-precision electrochemical device designed for critical water quality monitoring in industrial applications. Also known as a 4-20mA pH probe, this sensor also performs well in water treatment, food processing, chemical manufacturing and other harsh environments. Its core advantage is the transmission of measurement data via a 4-20mA current signal - the industry standard for reliable long-distance communication in harsh conditions.

Technical Significance of 4-20mA Signaling

The 4-20mA current loop standard was engineered to overcome industrial challenges like electromagnetic interference and cable resistance variations. Operating between 4mA (representing pH 0) and 20mA (pH 14), this linear analog signal ensures:

- Immunity to cable length and contact resistance

- Transmission distances up to several kilometers

- Live-zero fault detection (4mA = device active)

- Seamless integration with PLC/DCS systems

Understanding pH and Its Industrial Impact

pH - the "Potential of Hydrogen" - measures solution acidity/alkalinity through hydrogen ion concentration. In industrial processes:

- Drinking water requires pH 6.5-8.5 to prevent corrosion

- Wastewater treatment relies on pH stability for biochemical reactions

- Chemical processes depend on precise pH control for reaction efficiency

Accurate PH Measurement directly impacts product quality, equipment longevity, and environmental compliance.

How 4-20mA pH Sensors Work?

These sensors use electrochemical technology with glass or platinum electrodes to detect hydrogen ion activity. Key advantages include:

4-20mA Output: The sensor employs a 4-20mA current loop for signal transmission, ensuring compatibility with a wide range of industrial controllers and PLCs. This method of signaling provides enhanced noise immunity and the ability to transmit data over long distances without significant signal degradation.

Advanced Electrochemical Technology: The sensor incorporates either a glass electrode or a platinum electrode, depending on the Specific Application requirements. These electrodes are designed to provide accurate and stable pH measurements over a wide range of conditions.

Wide Measurement Range: The sensor has a measurement range of 0~14pH, covering the entire pH scale. This ensures that it can be used in a variety of applications, from acidic to alkaline environments.

High Accuracy and Resolution: With an accuracy of 0.1% or ±0.02pH (whichever is greater) and a resolution of 0.01pH, the sensor delivers precise pH measurements that are critical for many industrial processes.

Automatic Temperature Compensation: The sensor features automatic temperature compensation to ensure accurate measurements even in fluctuating temperature environments. This eliminates the need for manual adjustments and simplifies the measurement process.

Robust Construction: The sensor is constructed with durable materials such as PPS, ABS, POM+Stainless Steel 316L, or Titanium, and has an IP68 rating. This ensures that it can withstand harsh industrial conditions and provides long-term reliability.

RS485 Modbus RTU Communication: The sensor supports RS485 Modbus RTU communication, allowing for seamless integration with automation systems and remote monitoring capabilities.

Fast Response Time: With a fast response time of T90<10s, the sensor provides real-time pH data that is essential for process control and optimization.

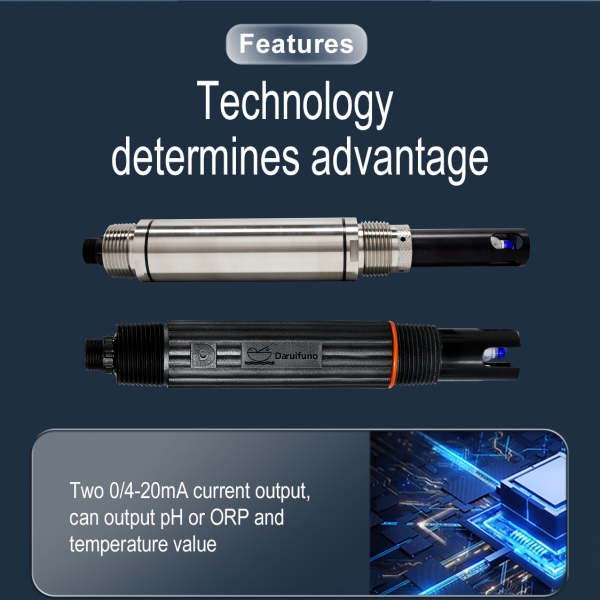

Why Choose Daruifuno 4-20mA pH Sensors?

Daruifuno sensors deliver unmatched performance for mission-critical applications:

- Advanced electrochemical technology with glass/platinum electrodes

- 316L stainless steel/titanium construction (IP68 rated)

- Dual output options (4-20mA + RS485) for flexible integration

- Proven reliability in water treatment, food/beverage, and aquaculture

Explore our efficient water quality monitoring solutions to optimize processes and reduce operational costs.

Technical Specifications at a Glance

| Parameter | Details |

|---|---|

| Measurement Range | 0-14 pH |

| Accuracy | ±0.02 pH |

| Resolution | 0.01 pH |

| Response Time | <10 seconds (T90) |

| Output Signal | 4-20mA / RS485 |

| Protection | IP68 |

Applications Across Industries

4-20mA pH Sensor,4-20mA pH Probe,4-20mA Current Loop

Suzhou Delfino Environmental Technology Co., Ltd. , https://www.daruifuno.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)